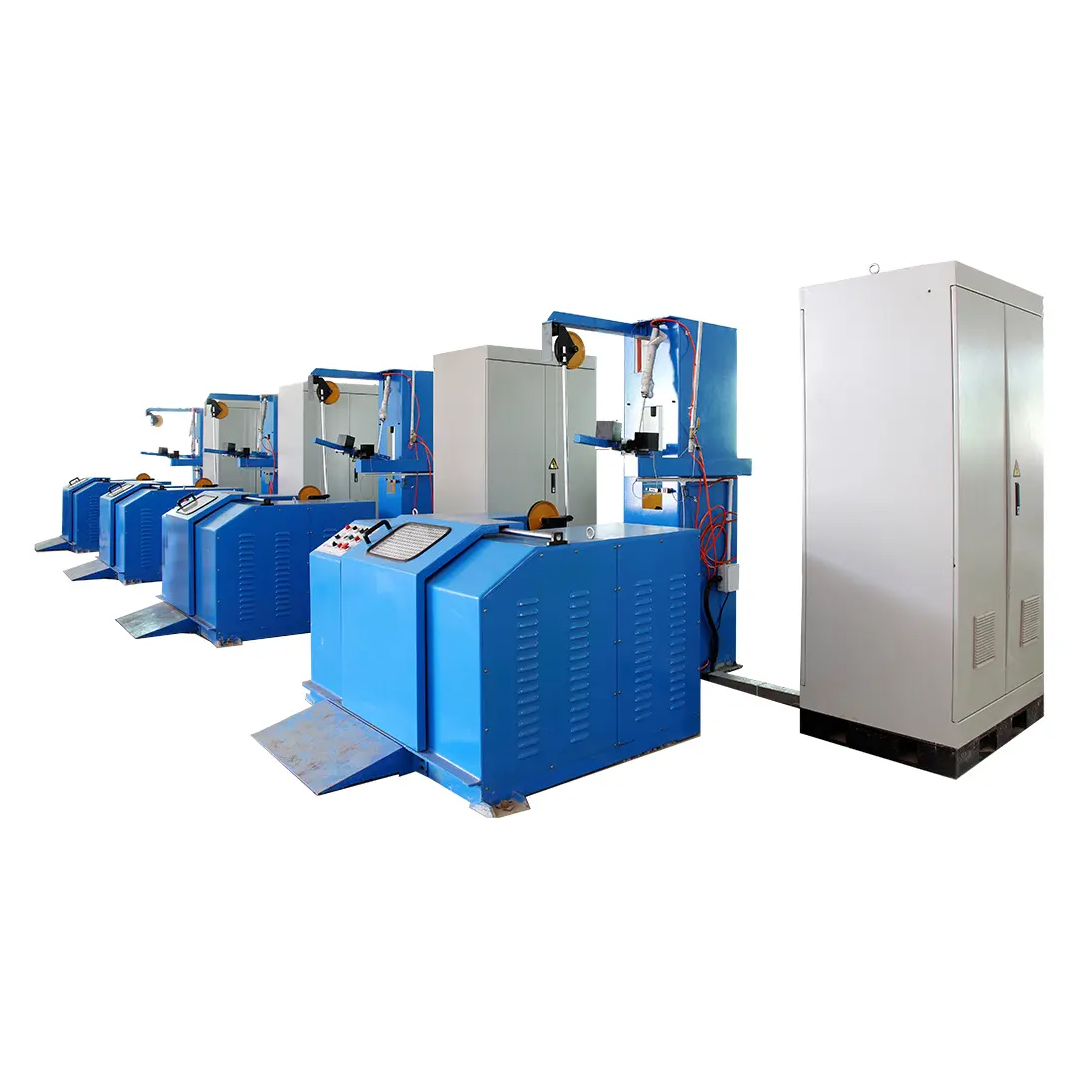

Double twisting machine Pay-off

Introduction

Efficiency: The design of the payoff frame enables the wire to be spooled and placed in a highly efficient and stable manner, improving productivity.

Stability: Through advanced control system and stable structural design, the payoff frame can ensure that the wire remains stable during the payoff process, reducing the possibility of wire breakage and damage.

Flexibility: The payoff frame has the ability to adapt to different wire diameters and materials, making it applicable to a wide range of production needs and improving the flexibility of the production line.

Automation: payoff frames are often equipped with automated control systems that enable automation of the wire payoff process, reducing manual intervention and increasing production efficiency.

Scrap Reduction: Through precise wire placement and control, payoff frames minimize wire scrap and loss, reducing production costs.

Specification

| Model | Reel size(diameter × total length) (mm) | Stranded cross section (mm²) |

Inlet single wire range (mm) |

Twisting pitch (mm) | Main motor (kW) |

Rotating speed (RPM) |

| SNJ200 | φ220 × 150 | 0.0034~0.035 | 0.025~0.05 | 0.94~4.08 | 2.2 | 0 ~ 3000 |

| SNJ300H | φ300*180 | Max. 0.25 | 0.04 ~ 0.10 | 1.15~1.24 | 4 | 0 ~ 3000 |

| SNJ500A-C | φ500 × 320 | Max. 2 | 0.08 ~ 0.32 | 5.34~40.02 | 5.5 | 0 ~ 3000 |

| SNJ500E | φ500 × 320 | Max. 1.5 | 0.06-0.26 | 2.86~44 | 5.5 | 0 ~ 3000 |

| SNJ630C | φ 630 × 475 | 1.5 ~ 6 | 0.23 ~ 0.64 | 26.19~75 | 7.5 | 0 ~ 1570 |

| SNJ630P | φ 630 × 475 | 1.5 ~ 6 | 0.15 ~ 0.64 | 15.54~73.89 | 15 | 0~2200 |

| SNJ800 | φ800 × 600 | 2.5~16 | 0.25 ~ 0.8 | 34.56~181.76 | 15 | 0~1200 |

| SNJ1000 | φ1000 × 750 | Max. 20 | 0.4 ~ 1.5 | 34.55~181.76 | 22 | 0~800 |

Rod Breakdown Machine Line

Rod Breakdown Machine Line Single, Dual Wire Drawing Machine Line

Single, Dual Wire Drawing Machine Line Multi-wire Drawing Machine

Multi-wire Drawing Machine Online Annealing Unit

Online Annealing Unit Take-up Machine

Take-up Machine Wire Tinning Machine

Wire Tinning Machine Wire Enamelling Machine

Wire Enamelling Machine Wire Electro-plating Machine

Wire Electro-plating Machine Copper Cladding Machine (CCA)

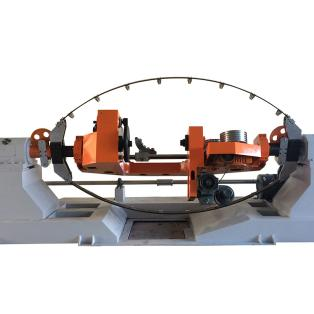

Copper Cladding Machine (CCA) Double Twisting Machine

Double Twisting Machine Bow Type Double Twisting Machine

Bow Type Double Twisting Machine Rigid Stranding Machine

Rigid Stranding Machine Tubular Stranding Machine

Tubular Stranding Machine Drum Stranding Machine

Drum Stranding Machine Cage Stranding Machine

Cage Stranding Machine